Essilor Mr. Orange Lens Finishing System

Mr. Orange is no longer available as a new system. It may be available as a Pre-owned system. Contact us.

Essilor Mr. Orange

Total Command of Your Jobs

30 degree tool inclination: Combined with lens geometry analysis, this range of movement provides outstanding results for all lens finishes (grooving, drilling, beveling) and base curves.

Fit-4-Frame technology: Variable geometry bevel with a dedicated chamfering wheel for shelf-beveling and fitting lenses in every form of groove regardless of the frame base

Designed to Change with Lenses

Star control process: Especially for hydrophobic treated lenses, this cycle offers outstanding control of the lens integrity (centering, edging, treatment resistance), irrespective of the material, shape, and finish.

Real-time control of cutting forces offers the best execution time and performance ratio.

Customized finishes: Customization of the finish parameters offers irreproachable results and guarantees a perfect fit under all circumstances.

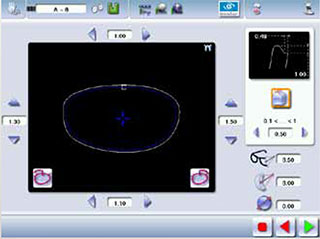

High Level of Tracing

Binocular tracing in 3 dimensions up to base 9

Feeler profile and inclination* designed to follow even the most complex grooves

Mechanical design recognized for its precision and regularity

*Essilor patent

Efficiency Based on Comfort

Centering space designed for all lens geometries, including curved large diameters and recut lenses

Hand rest and front-loading blocking arm designed for ambidextrous use

Soft touch finish of the centering range for work comfort and more accuracy

Precise Centering Strategy

Centering aid: Real-time orientation and validation of the best centering position

Centering free from all prismatic effects, irrespective of the lens power

Automatic adjustment of decentrations depending on the frame parameters (curve angle, base and pantoscopic tilt) and the wearer data

Traces between the Lines and Stores Data Twice as Fast

Optical Tracing!

Simultaneous acquisition of the shape and drilling data

Direct tracing without handling the lens or any accessories

Simple, easy access to the shape and drilling libraries